Your printing material passes through the feeder, the bowden tube, and the extruder on its way to becoming a printed object.

#Cetus3d restart print how to

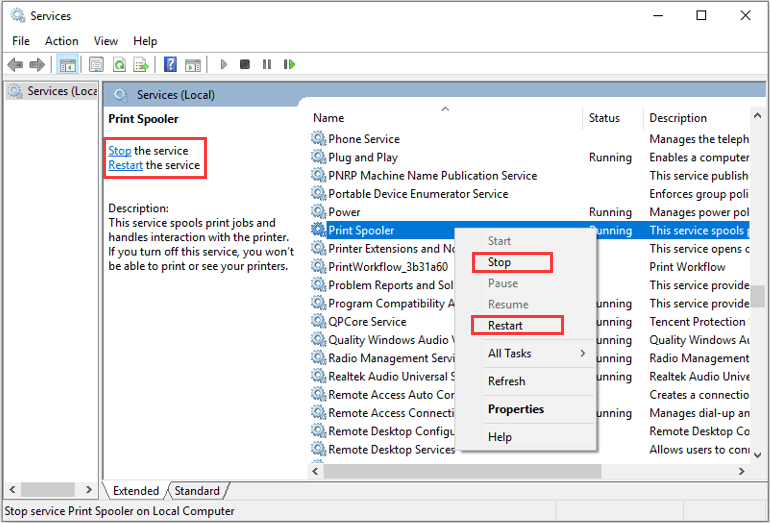

Let’s look at how to fix under extrusion. Often, it can just all be about finding the right temperature for your filament, with your printer. So, if you are printing at the correct temperature and you’re still having problems, it’s not a bad idea to try slightly raising or lowering the temperature that’s displayed to see if that clears up the under extrusion issues. That being said, it should be noted that it’s common for thermistors and heated thermostats to be somewhat inaccurate. Sometimes, PLA or PVA filaments if printed too hot can burn or crystalize in the nozzle, blocking it.Ĭheck to be sure you are printing within the recommended temperature parameters for the material you are using. This causes a partial blockage of the nozzle, and under extrusion is the result. Likewise, if the material is being printed at a temperature that is too hot, it can begin to fuse or bind to the inside of the hot end. It takes more force to extrude and the flow of the material is uneven as a result. The thermoplastic being used becomes thick and viscous. If a material is being printed at too low a temperature, it does not melt evenly. The most common cause of under extrusion is printing at temperatures that are either too high or too low for your material. In this article we’re going to examine some of the common causes of under extrusion, and give you a quick fix for each. Nonetheless, in many cases, you can solve the problem in short order simply by knowing what to look for. There can be various reasons why under extrusion is occurring, which can make it a somewhat thorny issue to deal with. Under extrusion occurs when your printer is unable to supply the correct amount of material needed to correctly print a layer. My print turned out spongy… These are the effects of under extrusion Every 3D printer’ users worst nightmare, waking up to this after an overnight print. There are missing print layers, thin printed layers, or even layers that have gaps and holes. The object you’ve been printing may look like it’s been exposed to an erosive or corrosive process. Sometime later, you come back to see how the job is progressing only to find that something has obviously gone wrong. You leave the room thinking all is right with the world. There appears to be adequate adhesion to the print bed and everything seems to be layering just as planned. Everything starts smoothly and looks good. If you moved the Z-axis mounting plate the right amount, you should now be able to calibrate your Cetus3D printer.Īnd what a printer! After calibration, the printer has been running 24/7!Ī minor snag on an otherwise excellent printer!.Has this ever happened to you? You set up a print job to run. Retighten the nut that holds the attachment rail and re-assemble the Z-axis. Lean the whole assembly back and loosen the hex screw for the Z-axis adjustment plate using the supplied wrench.

You have to remove the three screws that hold the Z-axis. When they assemble the Cetus3D in China, sometimes they don’t adjust the height of the Z-axis good enough.

But there is an easy fix for the problem. When I started through the steps to calibrate the printer by adjusting the build plate height, but the print head/nozzle refused to get close enough to the build plate to finish the calibration! The cables on the motor came in contact with the chassis of the printer! So the injector was 5mm from the build plate and couldn’t get any closer by increasing the step values. After finally getting my Cetus3D MkII 3D-printer I was eager to start to print.

0 kommentar(er)

0 kommentar(er)